Transformer Cooling Methods - Cooling Methods of Transformers

Losses occurring in the transformer appear in the case of heat, which increases the transformer's winding, core, insulating oil and tank temperature. If the transformer is not cooled to the allowed temperature, the transformer may burn. The temperature of different parts of the transformer is kept at the allowed temperature range through different cooling methods. The transformer is used for insulating and cooling purposes. This method is not enough in large rating transformers. Transformers rating and size increase the losses in these transformers too. For the purpose of cooling these transformers, various methods such as natural air, forced oil, forced air, water forced are combined or used separately for cooling of the transformer. The choice of method depends on its rating, size and location of use

Different methods are used for cooling of the transformers.

Cooling of Dry-type Transformers

- Air Natural Type

- Air Forced Type

Cooling of Oil Immersed Transformers

- Oil Natural, Air Natural Type ( O.N.A.N )

- Oil Natural, Air Forced Type ( O.N.A.F )

- Oil Forced, Air Natural Type ( O.F.A.N )

- Oil Forced, Air Forced Type ( O.F.A.F )

- Oil Natural, Water Forced Type ( O.N.W.F )

- Oil Forced, Water Forced Type ( O.F.W.F )

Air Natural Type ( AN )

Typically dry-type transformers with a rating of less than 25KAV are cooling this way. These transformers are cooled by the surrounding natural air. The natural air collides directly with the core and winding. These transformers are highly resistant to moisture and are not at risk of fire. This method of cooling is used in low rating instrument transformers.Air Forced Type (AF)

This method of cooling is commonly used in all dry-transformers of more than 5 ratings. The core and windings of these transformers are enclosed in a metal box with sharp fans that allow the winding temperature to reach a certain limit. In case of excess, automatically turn on and lower the temperature. Some transformers have fans mounted on the tank surface and cool the air by throwing cold air over the tank surface. This method is also called an air blast cooling method.

Oil Natural Air Natural ( ONAN )

This method of cooling is widely used in oil-filled transformers. This method of cooling can be used in transformers up to 100 MVA rating, but for this purpose, the size of the transformer is very large, which will increase the cost of the transformer. And more space is required so it is not commonly used in transformers of more than 30 MVA ratings. In this method of cooling, the core and windings are completely immersed in the oil and they are closed to a metal tank, which keeps it cool by hitting the natural air on the surface when the oil is heated by the heating of the core and winding. If the hot oil goes up and the cooling oil goes down the surface and the hot oil goes away from the core and winding and the cooling oil replaces it, this way the transformer cools down. The tubes are mounted on the outer surface of the tank to increase the cooling area.Oil Natural Air Forced ( ONAF )

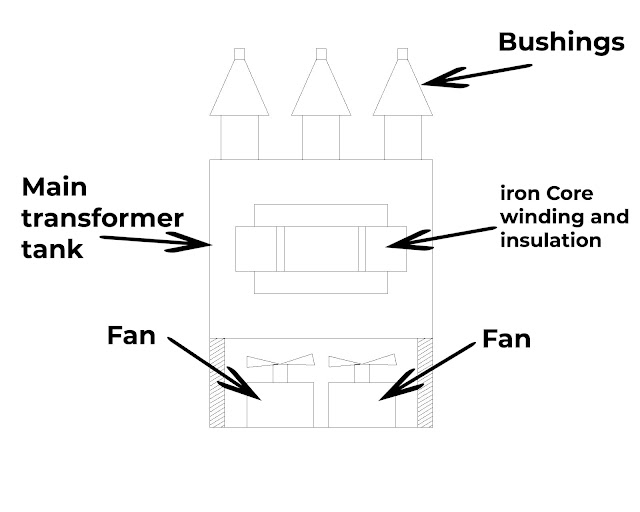

Core and winding in these transformers are submerged in the oil, naturally, they are cooled through the circulation of the oil, but in this cooling method, the fan is fastened to the outer surface of the transformer to achieve better cooling. These fans also apply to cool to the transformer tank surface or to the outside tubes by cooling it when the transformer oil and winding temperature increases by a certain amount, then the thermostat switch turns the fans ON. Thermostat switch closes the fans when temperature low. This method of cooling allows for higher rating Used in transformersOil Forced Air Natural ( OFAN )

In this method of cooling, the transformer's core and winding oil are submerged and the transformer oil is rotated rapidly from top to bottom via the pump motor. The pump motor also has a radiator or heat exchanger. The fan is fitted and it runs through the fan motor. The oil passes through the radiator. The air through the fan to the oil which cools the oil. This method of cooling is less used.

Oil Forced Air Forced ( OFAF )

Transformers of more than 60 MVA rating are usually used in combination with oil forced and air force modes. This cooling method involves immersing the core and winding oil and installing a cooler or heat exchanger separately near the transformer surface. It is connected to the heat exchanger transformer through the pipes up and down. Oil is circulated rapidly through the pump. The hot oil is moved to the heat exchanger and fanned with the heat exchanger. Transformers that cool the oil coming from the tank This cooling method is used in high-rating transformers applied to substations and power stations. This is the best method of cooling Transformers

Oil Natural, Water Forced ( ONWF )

In the cooling method, the cover and winding are immersed in oil and the cooling coils or tubes of copper are placed near the surface of the oil inside the tank. Cooling water circulates through the cooling coils or tubes. Water is absorbed with cooling coils or tubes that are added to the fan, which adds to the cooling. This method of cooling is used where the water head is high. This method is cheaper due to the high availability of water. The biggest disadvantage of this method is that in case of leakage of water, the oil is damaged and the oil dielectric strength is reduced.

Oil Forced, Water Forced ( OFWF )

Heat exchanger and pump motor are fitted with transformer in oil-forced, water-forced cooling method, and the heat of the transformer oil is cooled by rapid rotation of the oil and water through the top and bottom of the heat exchanger. The side is connected through pipes. The pressure of the cooling water in the heat exchanger is kept below the oil pressure. The pump pumps the motor oil through the upper pipe towards the heat exchanger. Transformers used at large substations and power plants usually use this method of cooling.

0 Post a Comment:

Post a Comment